What to make paths in the country cheap and beautiful?

DIY tracks can be made from a variety of materials. They can be classified into 2 main types.

- Not removable.

- They are made from traditional materials:

- clinker brick;

- tree;

- pebbles or natural stone;

- jellied of concrete;

- made using forms.

- Removable. As a rule, they are set for the summer period. They can be produced independently, or purchased ready-made.

The use of any building material has its advantages and disadvantages, their detailed analysis is given in the table.

Tracks are divided into 2 types. Removable and non-removable.

Each building material has its own characteristics.

The path of their stone will last a very long time

Table 1

Comparative characteristics of various types of garden paths

|

Types of Garden Paths |

Benefits |

disadvantages |

|

Made of natural stone |

Durability, resistance to mechanical stress (passage of garden equipment), high aesthetics, a wide selection of shapes and textures |

High cost, when moisturized, it becomes slippery, and in winter it is covered with ice crust |

|

From paving slabs |

Versatile, affordable material |

Unprofessional masonry can lead to distortions and differences, which will sharply reduce decorative |

|

Clinker Brick |

Durability, durability, inexpensive price. |

Brick laying should be carried out on concrete mortar, since sand does not provide reliable fixation of the material |

|

From wood |

Availability, originality |

Durability, instability to mechanical influences |

|

Concrete path in the garden |

Durability, strength, frost resistance |

The complexity, the need for formwork |

|

Plastic modules |

Low cost, easy styling, decorative |

Limitations on air temperature from -35 to +50 C |

The path made of natural stone will last a very long time

Choose materials based on your own preferences

Content

- 1 DIY garden paths. Professional recommendations, drawings and design options

- 2 Garden paths made of natural stone

- 3 Building a track without cement

- 4 Paving slabs

- 5 Clinker Brick Garden Paths

- 6 Wood Track Options

- 7 Concrete path in the garden

- 8 Concrete track pouring method

- 9 Benefits of using track molds

- 10 Jellied garden paths and their advantages

- 11 Modern idea - plastic modules

- 12 Video: DIY Garden Path

- 13 50 photos of ideas for creating garden paths with your own hands:

DIY garden paths. Professional recommendations, drawings and design options

Marking - an obligatory stage of construction

The initial stage of the construction of the track with your own hands is marking. First of all, it is necessary to determine its width and orientation in the suburban area.

For marking, fixed pegs are used, on which the cord is pulled, and the side borders are sprinkled with lime. This method of marking allows you to visually identify the planned area of the paved road, taking into account the location of plants and other objects.

It is worth noting that the excavated space needs to be made a little wider than the planned path for the installation of borders. High-quality marking directly affects the strength and durability of the finished garden road.

First of all, you need to determine the size of the track

Just in case, make the styling area a little wider.

Laying plays an important role in the process of laying garden tiles

Garden paths made of natural stone

As a natural stone, the Altai river stone perfectly resembles. It is from him that beautiful mosaic images are obtained, thanks to a variety of sizes and colors: from light to dark gray. To create such a paved road, you will need tools:

- it is necessary to pick up smooth stones of various sizes;

- sand;

- rubber mallet;

- cement;

- sponge;

- level;

- water.

Harvesting the right amount of quality stone is the first step in creating a paved road.

Initially, all river stones are carefully sorted. If the marriage of the surface of the pebble is insignificant, then it can be used to build the path by turning the flat side up.

The next important step is the selection of a pattern that matches the width of the prepared path.

The basis for the picture can be squares. A drawing of curls will perfectly fit into them.

The sketched image is transferred to the prepared base. In order to avoid destruction of the entire structure, the figure should be placed in the indicated square, so that it is limited by the sides on all 4 sides to create the strength of the mosaic. Usually, curbs or formwork from boards are used for this, which are then removed after the hardening of each element of the mosaic.

Natural stone tracks look very beautiful

Natural stone will serve you a lot of time

Due to the fact that the base substrate is made of crushed stone, it is recommended that the marking be done with lime.

Then the sand-cement composition is mixed, in proportions of approximately 3 to 1 or 4 to 1. The resulting solution reveals a small strip on which a part of the mosaic pattern is laid. To smooth the surface, each pebble is slightly pressed into the hydraulic solution. The strips are laid out with insignificant areas, for convenient alignment of pebbles in them.

Oval pebbles with rounded edges gradually form a finished mosaic pattern of the path. If the mixture has hardened, then to level the surface, on pebbles, you can knock with a rubber hammer.

After laying out 1 strip, it is necessary to check its evenness using the building level. So, guided by the drawing, row by row, lined with lined stone coating. In its mosaic, it is possible to apply both small rounded smooth pebbles, laying them on an edge, and solid ones, if they correspond to the formed image.

It is also possible to use different colors of pebbles, for example, laying out 1 strip light, the second dark, or performing color dilution.

After one of the elements of the mosaic is laid out, it is poured with water through a spray. This will fix the hardening composition, and remove its excess.

So, dividing the image into separate components, they cover all parts of the garden road. As a result, the garden path is closely filled with natural stones.

Such material is not cheap

To make the track last longer, make a sand pillow

Natural stone is durable and not subject to mechanical damage.

Building a track without cement

The difference of this option is that when laying a paved road, cement is not used.

Crushed stone is also the basis, raw sand is poured on it, compacted and smoothed out by the “rule”. The level of the sand layer is always less than the level of the curb or formwork by 30 mm. It is with these values that the stones will keep on the plane. It is necessary to level the filled mosaic on a border.

Pebbles are easier to veneer not by 1, but at the same time stack them in rows, tapping on top with a hammer. The sand will need additional wetting.

The elevation of the pebbles must be checked regularly with a special building level.

Having laid out a specific segment of the mosaic, before the sandy base dries, you need to tap the plane one more time with a hammer, and then add more sand on top. The excess of such a backfill is then immediately swept away with a brush.

Next, the finished mosaic is poured with water through a spray.

After absolute drying of the filled surface, it is possible to walk another time along the plane with a brush.

When the sand level decreases after a couple of hours, it is necessary to duplicate the backfilling and watering again.

After another drying of the mosaic, all stones are wiped with a damp sponge.

The completed construction is wetted with a small amount of water every day for a week - this way the path “will accumulate hardness”.

If the installation process is conducted in an open space, in such a case that the canvas is not washed out by a shower, it is preferable to cover it with non-thick foam rubber. It has a porous structure that allows a certain amount of moisture to pass through, but will prevent the flow of water from washing away the sand.

If the paved road was built using formwork from boards, then already at the end of the masonry, it is necessary to strengthen the canvas with stone or brick borders.

You can lay out the track without cement

Compaction sand is used to lay tile without cement.

Paving slabs

Paving slabs are a strong durable material. The service life of this material is approximately 15 years if the laying technology is followed.

If it is planned to move and park cars along such a paved road, then the height of the tile should be equal to 60 mm. It is available in various types and sizes.

The sequence of works on the construction of the roadway.

- Creating a project plan and layout. Next, design and design of the layout of the tile is developed and selected.

- Determining the cost of materials.

- Laying the roadway.

Styling process:

- dig small holes in the ground under the curb;

- installation of a border around the perimeter of the path to secure the canvas;

- the base layer of gravel is laid;

- tile coating is being laid;

- filling tile joints.

Garden path can be made of many materials.

Garden path made of natural stone will last you a very long time

Garden path can be done with help. special forms

Clinker Brick Garden Paths

A rather durable and aesthetic road comes out of it. For its durability, it is recommended to select high-quality clinker brick.

The base beneath it, with a rolled up upper sand layer, must be smoothed out using the “rule”. It can be constructed from planks with flawlessly smooth and smooth end faces. The board must be 200 mm larger than the scale of the roadway. The angles of the lower component of the plank are equal to the thickness of the brick.

After leveling the sand stratum, the installation of side blocks begins, they are installed on a half-width rib in the ground with a rubber hammer. The sides are fixed: with borders; solution; or fittings. Then an additional layer of crushed stone is thoroughly pressed.

Having fixed the side parts at the edges, determine the type of pattern for the design of the middle part. They are laid out in two main versions, it is placed on the end or on its wide side.

For the strength of the masonry, the first row must be laid in length, and the next across the path, ramming the bricks into the sand base. However, for reliability, they are fastened with cement-based adhesive.

The solution is placed in such a way that its excess does not protrude over the masonry.

For durability, brick tracks are impregnated with a primer

What would the track last for a long time, you should choose high-quality materials

After laying all the blocks, the seams are filled with sand. It is evenly distributed with a long-bristle brush.

After hardening the solution, the formwork is removed.A crushed stone of medium fraction is poured along the edge and carefully compacted, and another layer of crushed stone is added over it.

For durability and brightness of the tone, the brick is treated with a penetrating primer, dried material is stained with a specialized varnish for stone.

Wood Track Options

Wooden garden paths do not require additional processing, therefore, are a durable option. Thanks to specialized processing, it is possible to extend their service life and protect them from moisture. The optimal material is larch and oak, as well as coniferous wood. The most inexpensive are considered bars and saw cuts of a tree, and a terrace board is the most expensive.

The ideal thickness of the bars should be 15 cm. They are laid on a sand foundation covered with a layer of gravel. This method contributes to the longevity of the garden path.

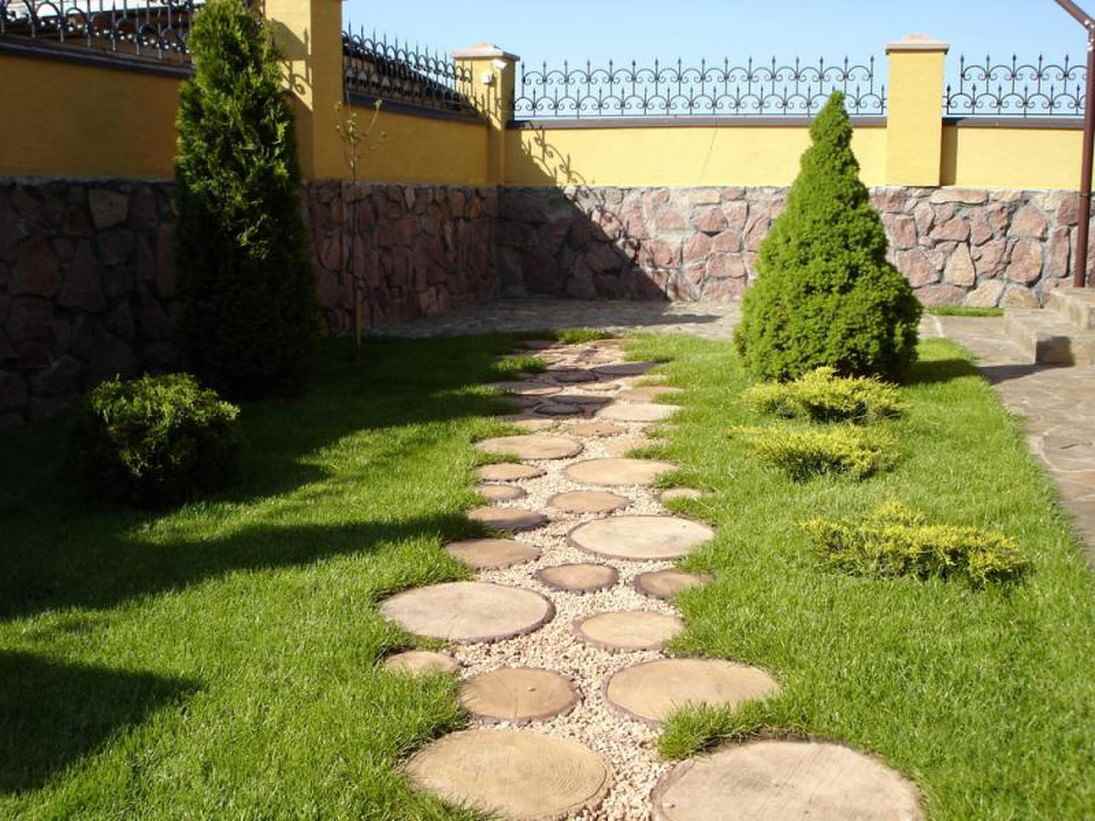

To create a more aesthetic option, wood cuts are used. They must be cleaned of bark and treated with drying oil. It is recommended to lay out the side parts from saw cuts of a larger diameter to increase strength.

Installation of a terrace board is carried out over a concrete surface. The advantage of this option is its high heat resistance, and the presence of a protective coating. These properties provide a high level of strength and durability to the decking. Fastening to the base is done using clips or self-tapping screws. However, this is the most expensive wood coating option.

Wooden garden paths do not require additional processing

A stone path will last you a lot of time

Concrete path in the garden

For a concrete road, marking is performed as described above, and then soil removal is performed.

Then, curbs or formwork are formed on the sides of the track.

A certain layer of sand is poured into the workpiece, then it is moistened and compacted. The final thickness of the sealed reservoir is 60 to 70 millimeters. Crushed stone is poured over the rolled sand, which also needs to be compacted. A reinforcing mesh is installed on the gravel, which makes the canvas significantly stronger.

Concrete track pouring method

To obtain a smooth plane, the finest concrete composition is formed, and the formwork of the path is poured.

Further reinforced concrete is leveled with the “rule”, the beacons in this case are the sides of the formwork.

Strength is created by “ironing”. Dry cement is poured onto a still dry plane with a thin layer, and it is immediately rubbed. It is also possible to use store topping mixtures.

Garden paths using form: benefits and technology

Benefits of using track molds

Of course, many people choose the most classic method of laying a track with tiles or paving stones. However, such a formation looks a little cliched, and it turns out to be quite costly. For this reason, almost all owners of country houses decide to build garden paths on their own plot using forms. This makes it possible to express imagination in landscape design.

The paths in the garden, laid out in this way, work out, as a rule, very elegant. And, in comparison with conventional technologies, they have important advantages, for example:

- minimum level of expenses for the system of work;

- the possibility of producing tracks of various dimensions and configurations;

- simplicity of the work execution process.

Creating paths using forms, they can be filled with various materials, for example: marble chips, pebbles and other materials that will create an original look for the path. However, before you begin to make paths, you should do some preliminary work on the marking.

Using a special form, you can build a very beautiful in appearance track.Such coverage is quite popular among summer residents and owners of suburban real estate due to the straightforward production and low cost of raw materials.

It is important to know that during the construction of the track it is necessary to take care of water disposal. To do this, it is possible to place it in elevated areas or to craft it at a certain angle for the flow of water. Otherwise, during the period of frosts, cracking of the coating may occur.

Jellied garden paths and their advantages

The filler coating is characterized by the highest strength and is perfect for loads. Paving of the filling tracks is performed on a concrete base. To form a system, paving stones or natural stone can be used. To form a natural look, multicolor material is used.

The easiest way is to bury concrete blocks in the ground. This option looks unusual and beautiful.

Garden paths are very useful.

The paths in the garden, laid out in this way, work out, as a rule, very elegant

Modern idea - plastic modules

Movable garden paths made of plastic modules are laid quite quickly, and do not require a base of gravel.

They allow you to build a road of any width you want, it is worth noting how they have fastenings that allow you to combine them both in length and across.

The connecting parts of plastic panels, which have rather huge dimensions, give the structure strength, so 2 plates are fastened at 2 points with the help of special mounts on the modules.

The advantage of such slabs is not only the mounting speed, but the fact that their plane is completely non-slip, quite impressive overloads withstand such tracks, and are very reliable.

For the production of plates used frost-resistant plastic. This material can withstand temperature fluctuations from minus -35 ° C to plus + 45-50 ° C. In winter, such a track can be quickly and easily dismantled, stored for storage in one of the household buildings. Plastic plates are practical and compact, the width and length is 570 x 570 mm, and the thickness is 22 millimeters. Due to the longitudinal openings, moisture from precipitation does not accumulate on the surface.

These garden paths are simple and easy to install, suitable for both lawn and ground. When germinating near plants, the path can be moved.

Video: DIY Garden Path